How Is Cask Whisky Made?

Discover the process of how cask whisky is made, from selecting the grains to distillation, ageing in oak barrels, and the intricate art of maturation.

Cask Trade

From Grain To Glass

It’s well known that whisky starts its life out as the humble grain, before eventually ending up as your favourite dram – but not as many are aware of what happens in between, and the process of how it gets there.

In this insightful short film, Cask Trade Director Colin Hampden-White guides viewers on a journey of whisky discovery, to tell the story of the life of the cask.

Table of contents

- Cask Whisky Production

- The Ingredients

- Malting

- Mashing

- Fermentation

- Distillation

- Cask Ageing

- Bottling

Cask Whisky Production

Single cask whisky starts life as a clear spirit made from malted barley, water, and yeast, which is then transferred into an oak cask to mature. The liquid needs to mature for a minimum of three years in the cask before it changes from being a simple spirit into whisky. The main difference between single cask whisky and the whisky you’ll see in the supermarket, is that is that the final flavour comes from one cask. This differs from the multiple casks being married together to create the volume and consistency of flavour you need for the mass market.

The following article will explore the whisky distillation process from grain to glass.

The Ingredients

Scotch Whisky is split into five types: Single Malt, Single Grain, Blended Scotch, Blended Malt, and Blended Grain.

Single malt whisky is made from 100% malted barley, whilst single grain can be made from the likes of rye, corn, and wheat - which is the most popular. Blended Scotch – which makes up 90% of Scotch Whisky sold around the world – blends the bold flavours of single malts with the more subtle single grains to create the refined and consistent flavour associated with blended Scotch.

The type of cereal used can make a difference to flavour. In malt whisky the older varieties of barley like Plumage Archer, will give different flavours to more efficient types used today.

The next key ingredient is water, if there is a high mineral content in the water then this may make a difference to distillation. But it is debated how much soft or hard water changes the flavour of a whisky production, due to the high temperatures used in distillation. On the other hand, much like tea, soft water is considered better for adding to a whisky when tasting. This is due to the higher levels of magnesium and calcium in hard water which can some say from the flavour of the whisky.

Finally, the yeast used in fermentation can make a difference to the taste of a whisky. Across the industry, distillers yeast tends to be the same, but in a few instances brewers yeast is used, such as at Benromach and Glen Garoich. Some distilleries use their own unique yeast strains for particular expressions, such as Dornach Distillery.

Malting

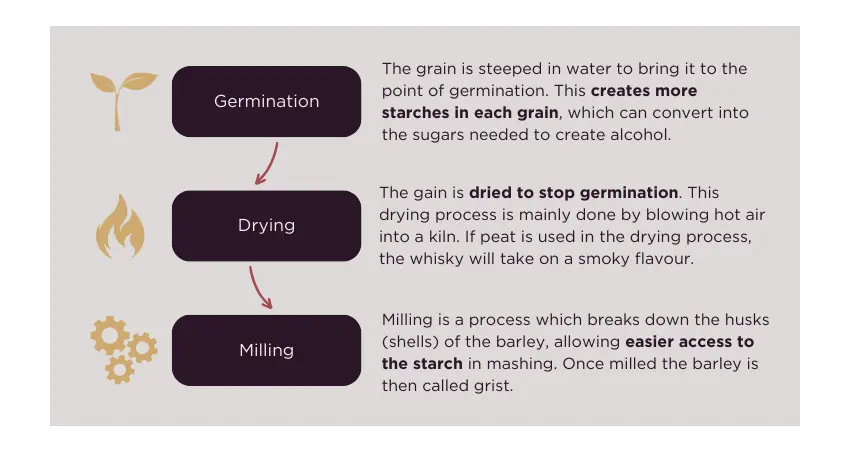

At the start of the whisky distillation process, the barley is malted. This process steeps the barley in water to bring it to a point of germination. This creates more starches in each grain, which can convert into the sugars needed to create alcohol. To prevent the grain from sprouting, it is dried to stop germination. This drying process is mainly done by blowing hot air into a kiln, Balvenie uniquely use anthracite - an efficient and low soot burning coal. Other distilleries use a form of decomposed vegetation called peat. At this point the flavour of the whisky can be heavily impacted, producing a smoky taste if the malted barley is dried with peat. Once dried the barley can be stored for months until needed.

The barley is then milled, a process which breaks down the husks (shells) of the barley, allowing easier access to the starch in mashing. Once milled the barley is then called grist.

Process of Malting

Mashing

Mashing is the process of adding heated water to the grist breaking down the starch and creates sugars which can then be fermented and turned to alcohol. Heated water is added in three phases, firstly at 62.5°C, then 75°C and finally 85°C. The result is a porridge like thick mixture. The liquid is then separated from this porridge which now contains all the sugars. The remaining barley husks, called draff, is usually used in cattle feed. The liquid is called wort, and it is the wort which is then fermented.

Fermentation

Fermentation will influence the flavour of a whisky greatly. Short fermentations will result in a nutty or grassy spirit, whilst longer fermentations will produce fruity spirit, with very long fermentation giving tropical flavours. This occurs with the different sugars being eaten by the yeast and turned to alcohol. The yeasts will eat the simple sugars like glucose and fructose first, followed by the complex sugars such as maltose and finally maltotriose, which give different flavours in whisky. Unlike beer, no hops are added. The liquid resulting from fermentation is called wash.

Distillation

Distillation can be done in a few ways. For grain whisky a continuous distillation is used, whilst for malt whisky a pot still is used. The liquid is distilled two or three times, the first distillation creating a liquor at around 20% alcohol by volume (called low wines). This is then redistilled to create a spirit of between 65% and 75%. The resulting spirit is then usually brought down with water to 63.5%, which is the percentage deemed the best for maturing whisky in an oak cask.

Cask Ageing

The process of aging in a cask is to impart flavour from the cask to the whisky. Before a cask is filled, it charred on the inside to act as a filter for the spirit. That filter will take out any unwanted or “off” aromas and flavours such as sulphur. There are many variables which influence the flavour of the final product, including the time spent in the cask, the environment in which it matures, and if any liquid has been held in the cask prior to it being filled.

Ageing time

In Scotland, spirit must be aged for three years to become Scotch whisky. After three years, the longer the spirit stays in the cask, the greater the flavour imparted to the spirit. There are certain flavours which sit in the surface areas of the wood, and others more deeply. Vanilla for example is found easily in the sprit after a short space of time, whilst spicy notes will take longer cask aging to achieve.

More recently, new make spirit (younger than 3 years old) has been a popular choice for whisky investment due to its affordable starting point options and long hold opportunity. Our Beginners Guide to Whisky Investment delves into more considerations and detail around choosing a cask to invest in.

Environment

The environment can make a big difference to maturation. As a cask matures it will lose both alcohol, known as the angels share, and water. In Scotland a cask will loss between 1% and 2% a year of alcohol, in a hot and humid whisky producing country like India, a cask will lose up to 15% abv each year and a good deal of water too. With hot humid conditions, faster loss of alcohol and evaporation of water the sprit will mature more quickly. There are even places in the world where whisky is produced and the alcohol percentage increases. This is in hot dry countries where a cask loses water more quickly than alcohol, Balcones Distillery in Texas is a good example of this.

Cask Type

How long whisky is left in the cask is determined by how active the cask is. If a cask has been used before it will take longer to mature the whisky, however the end result can be more nuanced. A cask which has been previously used for red wine or sherry will produce a sweeter liquid with a depth of flavour or colour. In contrast, a first fill oak cask will often produce lighter colours with more savoury notes.

Bottling

Scotch whisky must be matured and bottled in Scotland. Other countries and whiskies have varying rules. When the whisky is being bottled there are several decisions which are made. Firstly, what alcohol level is desired. Most supermarket whiskies are bottled between 40% and 46%. The also have a colorant E150 added so that the bottles are consistent in colour when sitting on a shelf, and consistent from year to year with the customers' expectations.

Supermarket whiskies are also filtered heavily. This is because when water is added to whisky there are particles which appear. Producers see this as unattractive, and “Chill” filter the whisky. This is a process of chilling the whisky to force these particles to appear and then filtering them out.

Independent whisky bottlers will tend to bottle the whisky at the natural strength it came out of the cask at, this is called cask strength, they also don’t colour or filter the whisky either. It is the most flavoursome and authentic way to drink whisky. Water can be added by the consumer to their own desired strength. Differently, much commercial whisky will be bottled at a relatively young age to supply the global demand for blended whisky and it won’t be at cask strength.

Conclusion

From water, yeast and barley, which is malted, mashed, fermented, distilled and matured for three years, comes whisky. These simple processes have been refined over centuries. Traditions have been built up during this time giving great quality of product. In this modern era these traditions are improved upon by innovation and technology giving us a product which is at its pinnacle when it meets your glass.

Each distillery will have built their own favoured traditions and ways of working. Our guides to Investment Grade Distilleries and Collectable Whisky Brands explore more of these differences in the age and types of whisky which make them desirable to different people.

Start your journey with Cask Trade

Learn more about the world of whisky investment via our helpful whisky investment guides. Alternately you can speak to one of our experts via email or over the phone. Simply register to be assigned a personal account manager who can talk you through the investment process and answer any questions you might have.

Based in Hong Kong?

With experts across the globe, we can help you no matter where in the world you are. Register on casktrade.hk to speak to our Hong Kong based team.